- Face

- Body + Hand

- Hair

- Candles

- Parfum

- Subscriptions

- Nutrition

- Gifts

- Treatments

- Visit

- Academy

- Journal

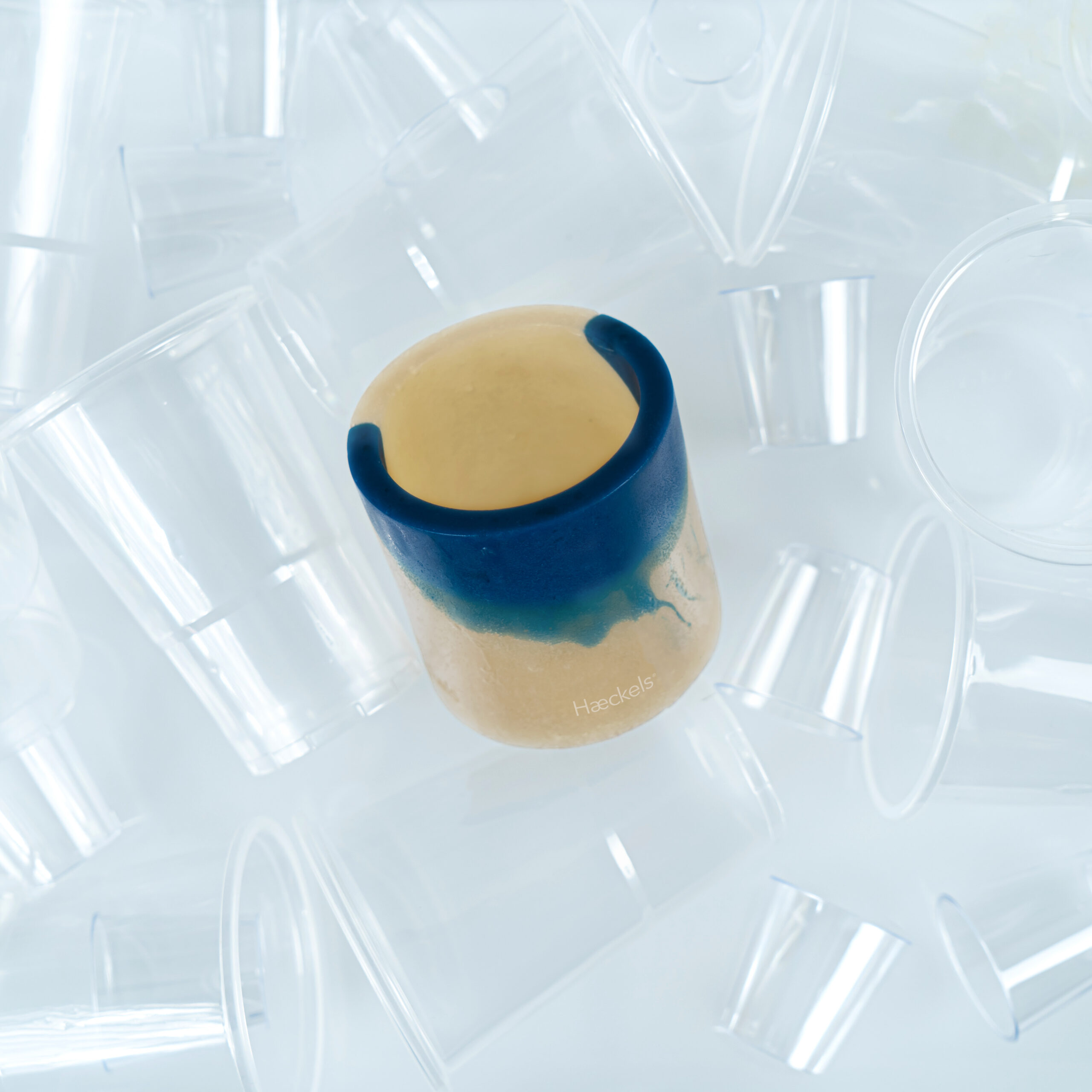

The dirt on our edible cup

The dirt on our edible cup

You’ve probably heard (and seen) nothing crazier for a skincare company to launch – an edible cup.

A friend approached us a number of years ago about working together to fix the waste problem at festivals. Approximately one hundred million single-use plastic cups are used yearly at festivals worldwide. Most paper cups are not actually recyclable due to a spray-on plastic lining to hold the drink within the paper.

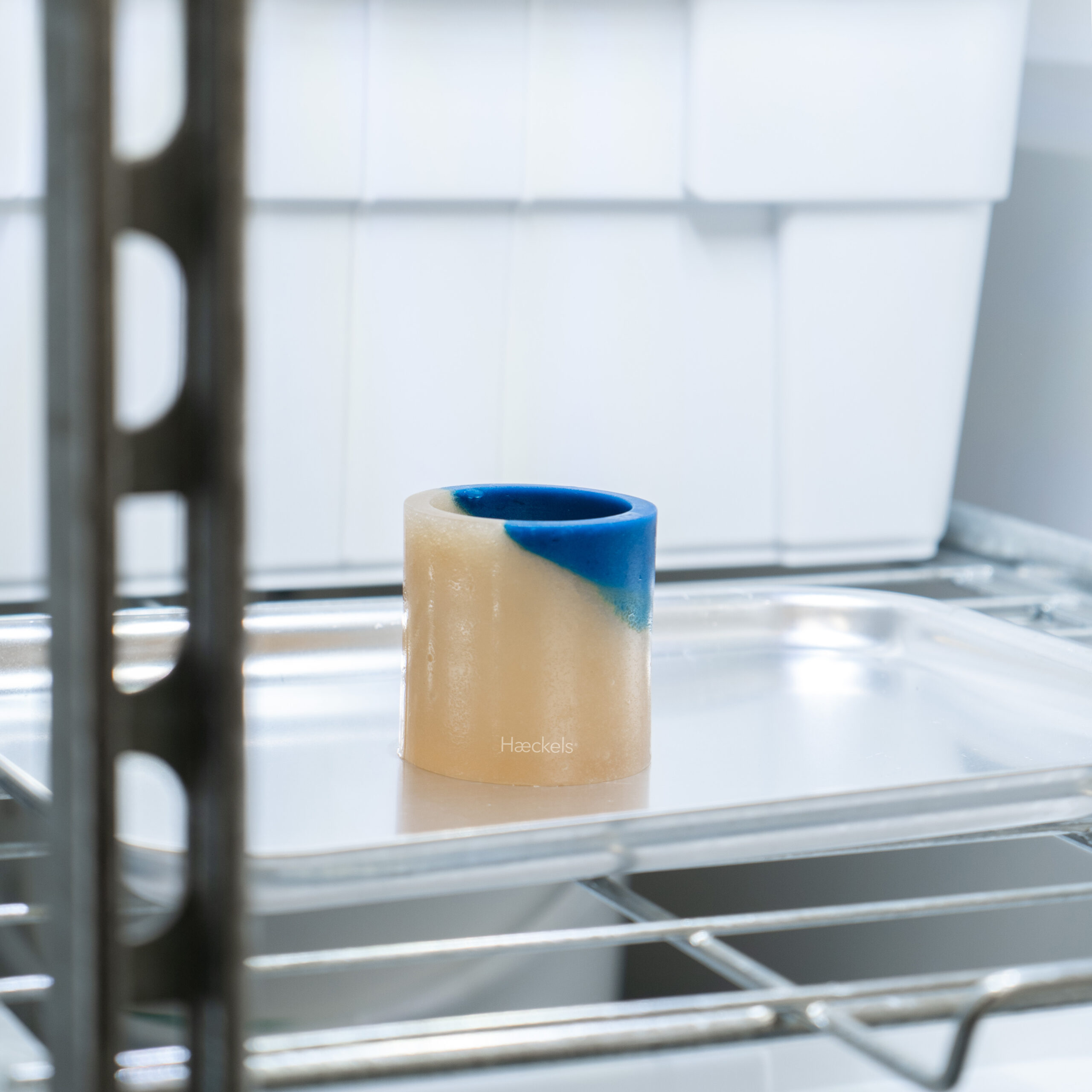

So we got thinking, and over the course of three years the idea snowballed through various different versions to land on something far greater than anything we’d done – an in-house designed and manufactured postbiotic edible cup made from a seaweed based material that we’d developed ourselves.

Read on below.

We wanted it to tackle the waste problem.

Our material fully composts within seven days. It’s made of seaweed, making it an excellent fertiliser for soil if it doesn’t get eaten. Seaweed also can help aid soil health.

To function as a cup, it needed to be able to hold liquids for over 48 hours and not lose its structure – which it does. The material itself holds liquid from its production process, meaning it has non-permeable walls.

We wanted it to do the body good.

We designed the cup as a postbiotic to aid in gut health, as the material has properties that enable it to be infused with ingredients. This was important as the body is stressed at festivals and events. We used ingredients such as spirulina, blueberries and ginger to aid digestion, promote collagen synthesis and help energy and mood.

It was our first commercially available supplement. Of course, for those following us closely, you will know that gut health is intricately linked to our future.

And finally, we wanted it to look good.

The entire manufacturing process was designed in-house. Our team of scientists, designers and engineers helped to create a process where we shifted from a skincare manufacturer to a cup manufacturer almost overnight. We created our own shapes, moulds and techniques, making this a truly Haeckels concept from start to finish.

—

Material innovations are the beating heart of our lab and future work. We believe in innovating through the confines of our walls, developing our materials and ways of manufacturing things. There is much more to come from this groundbreaking material.

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept All”, you consent to the use of ALL the cookies. However, you may visit "Cookie Settings" to provide a controlled consent.Manage consentPrivacy Overview

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.Cookie Duration Description cookielawinfo-checkbox-analytics 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". cookielawinfo-checkbox-functional 11 months The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". cookielawinfo-checkbox-necessary 11 months This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". cookielawinfo-checkbox-others 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. cookielawinfo-checkbox-performance 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". viewed_cookie_policy 11 months The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet.Free UK shipping via Royal Mail when you spend over £65 - Body + Hand